The Need For Better Body Lab Models

Finding and testing new drugs is always a complex and expensive process. Historically, it was entirely reliant on testing the new products on animals and humans.

İçindekiler

More recently, in-vitro testing has been used to see what a potential new pharmaceutical could do to specific cell types.

However, the relevance of in-vitro studies is always uncertain, as the whole body, animal or human, is very different from just a cell culture. An anti-cancer chemical might be absorbed by the gut, processed into a new molecule by the liver, and have unexpected effects on the brain. None of these processes will be correctly identified with just a culture of cancer cells.

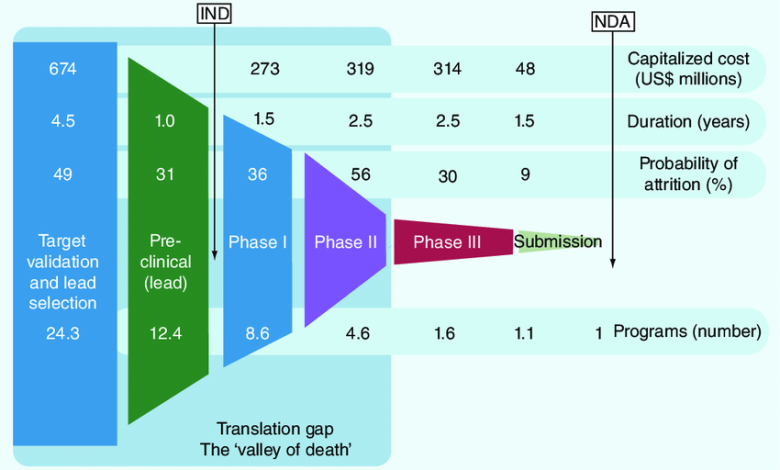

This is far from just an academic issue, as many potential drugs fail in phase I of clinical trials, revealing safety issues that animal and in-vitro studies failed to identify early enough.

This, in turn, costs a lot of money and increases the cost of future life-saving drugs.

Source: Research Gate

Luckily, a new technology might be coming to the rescue, with a much more accurate simulation of a full body in lab settings.

Organ-On-A-Chip

“Body-on-a-chip,” also called “human-on-a-chip” or micro physiological systems, look to replicate fully or part of a body with cell cultures.

To do so, it connects together multiple miniature in vitro organs (“organ-on-a-chip”).

Source: Harvard

Organ-on-a-chip is a technology using microfluidics to supply nutrients to the cell culture, creating a realistic simulation of the diffusion of nutrients and drugs into a real organ.

For example, this can create a model of an “airway-on-a-chip” simulating how the human airways work, as well as models of human intestines, kidneys, or bone marrow.

From Organ-On-A-Chip to Body-On-A-Chip

By combining multiple organ-on-a-chip systems, you can start creating parts of a full body and properly consider the biological process a drug would be performing in a real patient.

This can imply biological mechanisms as diverse as immune response, drug absorption in the gut, lungs, or blood vessels, muscle contraction, liver metabolizing, etc.

Source: Harvard

Once again, this is crucial, as most drug effects (positive and negative) can only be understood if taking into consideration many different organs’ reactions to it.

Body-On-Chip Designs

Not all body-on-chips are made the same, and many different designs exist for the organ-on-chip used to build the whole system. Each has its own advantages and is used differently by medical researchers.

One way to categorize them is by the type of cell and tissues used. Some organ-on-chips use only one cell type (monoculture), supported either by artificial microstructures or collagen layers. Others have multiple cell types assembled together, either in spheroids or in more complex 3D structures.

Source: Nature.com

Another categorization method examines how fluids are transferred into and between the organ-on-chips. They can share the same ambient fluid, or be linked through a custom-design of tubes replicating the blood or lymphatic system. The liquid flow can be continuous or controlled by robotic fluid transfers.

They can also be separated from the circulating fluid of nutrients and drugs by a porous membrane or a layer of cells (endothelium).

Source: Nature.com

As you can imagine, this diversity of designs creates almost endless possible combinations. So while already very useful, researchers are only at the beginning of designing organ-on-chips and body-on-chips and are still experimenting to find the optimal balance between perfect replicas, reliability, and production costs.

Organ-On-Chip Market

Organ-on-chip is a new technology that is only now reaching enough maturity to exit the research lab and enter the drug development process. In 2023, it was a $103M market.

Estimates put the market for organ-on-chip at $303M by 2026, with a quick growth from replacing animal testing putting an estimate for 2027 at $529M. Other forecasts see it growing to $1.4B by 2032, doing more than 10x in 8 years.

Body-on-chip is even more recent and will greatly benefit from technological innovation to improve its performance and reliability and reduce costs.

Body-On-Chip Applications

Pharmacokinetics

A key characteristic of drugs that deeply impacts their effectiveness and potential toxicity is “pharmacokinetics”. In simpler terms, it is how quickly the drug will diffuse in the body and each organ’s tissues individually.

This is hard to predict on paper or computer models, as it depends on how the guts, bloodstream, and organs will react to a specific chemical.

For this, as complete as possible body-on-chips are required, with the drug’s entry point varying whether it is administrated orally (stomach and guts), in aerosols (lungs), or intravenously (bloodstream).

Source: Nature.com

Personalized Medicine

Another big promise of body-on-chip is the potential for personalized medicine. Increasingly, researchers and biotech startups are looking to develop drugs not just for “humans” as a whole but adapted to sub-categories (sex, ancestry, age, genetic profile, etc.) down to the individual patient.

Thanks to their high replicability, no health risks, and lower cost, they can advantageously replace many clinical trials in fine-tuning a drug in the early stages of development.

For example, they could help in the identification of alternate drug candidates when safety issues arise, especially if the issue only affects a specific sub-population.

Source: Nature.com

Initially, body-on-chips will mostly have to demonstrate their superiority to existing in-vitro and animal studies.

However, the ultimate goal will be the accurate replication of in-vivo patient clinical trials.

In an even more distant future, we could imagine that body-on-chips containing the patient’s own cells could be used to predict in advance the reaction to various drugs and determine the best therapeutic method.

3D Printing To Help Make Body-On-Chips

Real organs are complex 3D structures with an intricate mix of different cells and tissues.

In order for the organ-on-chip making up the full body-on-chip to realistically simulate the real deal, there is a need for the manufacturing process to create an almost exact replica of real organ tissues. Or, in the future, maybe even fully-grown organs.

This will only be possible thanks to an emerging technology called bioprinting.

It reuses the key principle of 3d printing: a nozzle is controlled by a computer and deposits the wanted material in the right place, bit by bit. But instead of depositing plastic or metal, it deposits living cells.

Bioprinting has evolved in parallel to organ & body-on-chip technology, with initially more of a focus on solving the technological difficulty in “printing” with cells.

Currently, the industry still mostly relies on artificial scaffolding to give structure to the printed cells. However, progress has been made in creating 3D-printed organs that are more similar to organic ones.

So, if the current organ-on-chip mostly recreates a template of the multi-layers forming an organ’s tissues, combining it with advanced bioprinting methods could create even more realistic simulations.

If you would like to read to know more, we explored in-depth bioprinting in our articles “Organs On Demand: Best 3D Bioprinting Stocks” and “New Technique Allows 3D Printing of Functional Brain Tissue”.

Bioprinting And Body-On-Chip Companies

1. BICO Group AB (BICO.ST)

In 2021, Cellink was renamed as the BICO Group, following its acquisition of Cytena lab automation tools in 2019 and Scienion high-precision micro-drop measuring tools in 2020.

Cellink is still the brand name for the bioprinting part of the business.

While not alone in the field, Cellink is clearly a very advanced bioprinting equipment manufacturer, with a focus on supplying researchers in biotech and biomedicine.

In the long run, bioprinting companies are likely to evolve from providing tools to researchers to becoming suppliers of pharmaceutical companies’ bioprinting therapies for patients. This will, in turn, completely change the number of bioprinters in use and, more importantly, the volume of consumables sold every month.

This is the same process that occurred for other biolab equipment manufacturers, including genome sequencing machines from PacBio (PACB) and Illumina (ILMN), which have ended up making 80% of their revenues from recurring sales of consumables.

2. Organovo

Organovo’s proprietary technology uses 3D-printed human tissues to mimic key aspects of real human tissues, including composition, architecture, function, and disease.

This was used to find new molecules with therapeutic potential. By first validating the potential molecules in the 3D tissue model, the company hopes to reduce the risk of failures in the clinical trials, due to a more realistic in-vitro cellular model before any testing is done on humans.

Organovo’s pipeline is focused on Inflammatory Bowel Disease (IFD) and liver fibrosis, with one program in phase 2/3 of the clinical trial and one in phase 1. The Phase 2a POC results are expected in 2H 2025.

Source: Organovo

There were 2.1 million cases in the US in 2022 and 13 million cases globally of ulcerative colitis, a form of IFD, representing a $6.6B market. It is also expected to keep growing at 6% CAGR until 2032, to a $12B market.

As Organovo uses a realistic simulation of the intestinal tissue, with polarized epithelium and interstitial layer, it is likely that they have a good representation in-vitro of how their drug will act for a patient.

Source: Organovo

It is likely that as body-on-chip becomes a more mature technology, the approach of Organovo to use 3D-printed human tissues will become even more likely to predict early potential problems in drug development.

This, in turn, should help it speed up drug discovery and use its capital more efficiently than competitors still relying on older methods.