Nanocomposite Electrocatalysts Could Reimagine Lithium-Sulphur Batteries with 5 Minute Charge Times

From Lithium-Ion To Lithium-Sulphur

Lithium-ion batteries have, so far, dominated the battery market. This is thanks to both high energy density and a head start from being widely used and produced for the electronic consumer market.

İçindekiler

When applied to other uses, limits to lithium-ion battery capacities started to appear. For example, lithium-ion batteries are relatively slow to recharge, and while fast charging is possible, it tends to damage the lifespan of the battery.

Slow charging has been a constant issue for EV owners and is often cited as a reason for people refusing to adopt electric vehicles.

With EVs now the largest consumer of batteries by power capacity, new battery chemistry that charges faster could become quickly popular and compete with lithium-ion designs.

One such promising new chemistry are lithium-sulphur batteries. Previous designs were even slower to charge than lithium-ion, but new nanomaterials could make a lithium-sulphur-powered EV charge in just 5 minutes.

Lithium-Sulphur Advantages & Challenges

The new lithium-sulphur battery technology was discovered by researchers at Chinese and Australian universities and research institutes (Adelaide, Tianjin, ANSTO, and Tsinghua) and published in Nature Nanotechnology under the title “Developing high-power Li||S batteries via transition metal/carbon nanocomposite electrocatalyst engineering”.

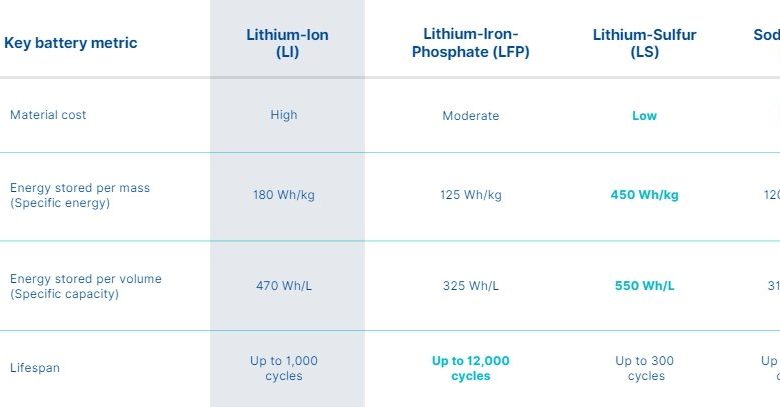

Lithium-sulphur batteries have long been known to offer amazing energy density, more than double the energy of classical lithium-ion batteries when measured in Wh/kg (specific energy), and superior performance when measured in Wh/L (specific capacity).

Source: Vertex Holdings

The key issues that stopped prototypes of lithium-sulphur batteries from being widely adopted so far have been low lifespan (1/3 of lithium-ion) and very slow charging speed, requiring 1-10 hours for a full charge.

Something obviously unacceptable for EVs, with users already complaining of the 20-30 minutes with lithium-ion.

(We discussed many alternative chemistries to lithium-ion in our reference article “The Future of Mobility – Battery Tech”).

Lithium-sulphur limitations have suddenly changed thanks to the recent discovery published in Nature, with a new lithium-sulphur design promising astonishing performances:

- Lifespan of at least 1,000 cycles, similar to lithium-ion.

- Specific energy of 1,306 Wh/kg, 10x more than lithium-ion, and even superior to most designs of solid-state batteries.

- Charge/discharge cycle of less than 5 minutes.

Building Lithium-Sulphur Batteries At The Nanoscale

So, how did the researchers manage to build what seems to be the perfect battery?

First, they examined at the atomic/quantum level the sulphur reduction reaction (SRR), the key part controlling the charge/discharge rate. To achieve this, they used a particle accelerator (Australian Synchrotron, ANSTO) to determine the exact atomic orbital occupancy (the position of electrons around the sulphur atom) in metal-based catalysts.

Armed with these never-before-analyzed data, they managed to predict accurately the speed and process of sulphur reduction reaction (SRR).

With this predictive model in hand, they then designed nanocomposite electrocatalysts, made of carbon and several different alloys of metal electrocatalysts like iron, cobalt, nickel, copper, and zinc.

Ultimately, an alloy of cobalt and zinc was selected, with the remarkable performances explained above.

What’s Next?

The development of such a “super battery” could be a tipping point in the electrification of our energy systems, from transportation to mass adoption of renewables requiring powerful utility-scale batteries.

It is, however, still early, and a few questions need to be answered before lithium-sulphur batteries take over.

Rare Materials

Lithium-ion batteries & EV manufacturers have been trying to move away from cobalt-using designs for years. This is because cobalt is a rare mineral, and its main source has been Congo, where cobalt production has been linked to child and slave labor and generally human rights abuses.

So, the cobalt-zinc nanocluster used in the electrocatalyst will also need to contend with that issue.

Costs

High material costs are another reason why the industry is moving away from cobalt-based designs in favor of batteries using solid-state, lithium-ferrum-phosphate (LFP), or sodium-ion.

So this could be an issue for cobalt-based lithium-sulphur batteries. Even if they are much more efficient and energy-dense than lithium-ion.

At the same time, an extremely high specific energy means that fewer batteries will be needed for the same EV range.

This, in turn, greatly reduces the weight of the EV, as batteries currently make up more than 25% of the vehicle’s weight. Lower weight increases the range even further.

The real determining factors will be the price per Wh of lithium-sulphur batteries, and how much lower the battery pack’s weight can go.

Mass Production

The last decade has seen plenty of innovative materials and designs in battery technology. But turning a lab-made coin cell into a battery pack, and then creating a factory-scale process to build them is not trivial.

For example, the date of commercialization for solid-state batteries has been repeatedly postponed year after year by QuantumScape, Volkswagen, Toyota, CATL, LG, etc.

This is not because the technology is not working, but that mass producing at scale solid-state batteries, without quality issues & at low costs, has proven very challenging.

So, there are likely still many steps ahead in turning this lithium-sulphur prototype into a commercial battery.

Conclusion

Batteries have been the weak point of EVs since inception, something getting slowly solved through the tremendous research efforts by universities worldwide, as well as industry leaders like CATL, Telsa, LG, etc.

It is unclear which design or chemistry will ultimately prevail. The strongest contender seems to be solid-state batteries, and lithium-sulphur may be the generation of batteries that will come after solid-state commercialization.

LFP and sodium-ion might also be around for applications and products focused on low costs instead of high performance.

And of course, maybe even more exotic designs for utility-scale batteries with very different requirements compared to EVs, like iron-air, redox, gravity, or concrete batteries that we discussed in our articles “The Future Of Energy Storage – Utility-Scale Batteries Tech” and “Non-Chemical Alternatives To Batteries For The Energy Transition”.

In any case, the future of energy systems trends toward mass electrification. And battery technology is advancing very quickly, which will likely remove the last roadblock toward mass adoption of EVs and renewables.