Graphene Made Of Boron

Material sciences keep making new discoveries, one of them being 2D materials. They are materials organized into a thin layer of only one atom, hence the moniker. The first one was single-layer graphene, which was produced with certainty only in 2004, although the idea and theory about it were much older, and which would lead to its discoverers winning the 2010 Nobel Prize in physics.

İçindekiler

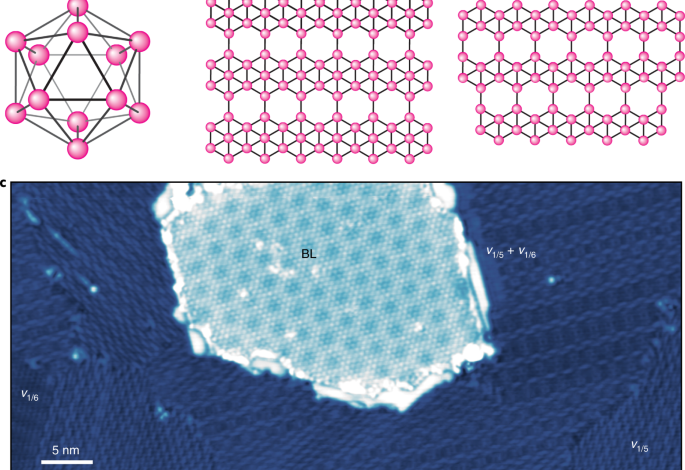

Borophene, another 2D material, is even newer, having been discovered only in 2015. It is made of boron atoms instead of the carbon atoms used in graphene. It is even more conductive, thinner, lighter, stronger, and flexible than graphene, despite graphene often being described as a miracle material.

Source: Nature

Because it is so new, we still know little about the actual properties and full potential of borophene. It is a material even more complex than graphene, with many possible molecular configurations possible while retaining its 2D properties. Borophene”s molecular structures can have space to accept other types of atoms, making the potential configurations even more numerous.

Source: Frontiers of Physics

And the potential of borophene keeps growing, as researchers at Penn State have discovered how to improve borophene, and also investigated how it interacts with living cells.

New Chiral Borophene

In a scientific publication titled “Chiral Induction in 2D Borophene Nanoplatelets through Stereoselective Boron–Sulfur Conjugation“, Penn State’s researchers focused on a unique feature of borophene among 2D materials, its potential “chirality”. Chirality is a chemistry term that means that molecules have a left/right symmetry. Chirality is an important feature of organic molecules, for example, the amino acids that are the building blocks of proteins.

Source: UC Santa Barbara

It is through the interaction with chiral amino acids like cysteine during the production process that the researchers managed to impart chirality on borophene, a world’s first for 2D materials.

In molecules, chirality can make biological or chemical units exist in two versions that cannot be perfectly matched, as in a left and right mitten. They can mirror each other precisely, but a left mitten will never fit the right hand as well as it fits the left hand.

Pr. Dipanjan Pan

Utilizing Chirality In Healthcare

The researchers synthesized borophene platelets, similar to how fragments of borophene would go into the bloodstream. They discovered that the chiral properties of the different versions of borophene interacted differently with the cells’ membranes, and entered the cells differently.

This opens the way to designing custom borophene structures for applications like the “development of higher-resolution medical imaging with contrast that could precisely track cell interactions or better drug delivery with pinpointed material-cell interactions.”

A better understanding of how borophene structure interacts with living cells will also help clarify its safety profile.

It could also lead to safer, more effective implantable medical devices that leverage borophene’s unique properties. Not only is it a very light and strong material, but borophene also allows for effective magnetic and electronic control.

So, borophene could also be used to develop biosensors or bio-mechanical systems.

Other Borophene Applications

Similarly to graphene, borophene is a promising material for many high-tech applications. Among them are:

These applications could potentially benefit from chiral borophene, and the new material will need to be tested for each separately.

Potential Borophene Companies

As a material discovered less than a decade ago, borophene is still quite far away from mass manufacturing and mostly confined to material sciences (and soon biology?) labs.

However, the way borophene was synthesized for the first time in 2015, a method called “chemical vapor deposition” or CVD, is not a new technology. It is commonly used in the semiconductor industry for producing integrated circuits and photovoltaic (solar panels) systems.

CVD is used to create ultra-thin layers of silicon, tungsten, graphene, and even synthetic diamonds. So any company already a leader in CVD equipment could become a prime beneficiary of the growing range of applications for graphene and now borophene.

CVD is part of the tools used by many semiconductors companies we listed in “Top 10 Semiconductor Equipment Stocks for Manufacturing Support”. But some companies are linked to CVD technology more tightly than others active in different parts of the semiconductor manufacturing process.

1. Veeco

Veeco has been a major supplier of equipment to the semiconductor manufacturing industry since its foundation in 1945. Its machines are used in producing advanced EUV chip making, 5G antennas, hard drives, LIDAR, LEDs, power electronics for EVs, etc.

Source: Veeco

The company’s technological main focus is the same CVD process used for borophene production, or more precisely MOCVD (Metal-Organic Chemical Vapour Deposition).

Source: Veeco

As a leader in this niche segment of the semiconductors industry, Veeco could be a good candidate to bet on the rise of more CVD applications stemming from the growing usage of graphene, tungsten, and borophene, as we progressively get better at manipulating matter at the atomic level.

It will also likely benefit from the massive trends of digitalization, AI, and electrification.

2. Ulvac (6728.T)

The Japanese company Ulvac is a specialist in vacuum technology, especially used in CVD and semiconductor applications. This makes it a key equipment supplier for producers of chips, LED, photovoltaics, batteries, etc.

Source: Ulvac

The company is also active in other markets, notably FPD (Flat Panel Display) like screens and TVs. It also produces parts in high-performance metals like titanium, tantalum, zirconium, niobium, etc., as well as industrial equipment for a very wide array of applications (internal combustion engine parts, magnetic materials, freeze drying or purifying of pharmaceuticals, vacuum drying of food).

Source: Ulvac Q3 2024

Ulvac technology is crucial for the CVD process, and its sales will likely benefit from new applications and growing demand for advanced materials requiring vacuum like batteries, chips, solar panels, magnets, LED, screens, advanced pharmaceuticals, etc.

However, thanks to the wider range of potential applications, it is less dependent on the semiconductor industry activity than pure CVD companies like Veeco.

Considering how cyclical the business activity can be for suppliers of semiconductor manufacturing equipment, this makes Ulvac a likely less volatile investment. It should also be less exposed to the brewing risk of trade wars between the USA and China in the semiconductor industry.